Long buried in the center of the periodic table, rare earth metals now find themselves at the confluence of national security, industrial policy, and key sectors of the economy. China controls the market for rare earths—and is using them as bargaining chips in its trade war with the U.S.

The Trump administration is taking steps to establish its own rare earths supply chain, including the Department of Defense’s recent stake in a rare-earth materials company. But ramping up processing of the minerals won’t happen quickly, because these crucial earth elements are difficult to extract and turn into useable commodities.

Are rare earths rare?

Rare earths are a group of 17 elements—the row from lanthanum to lutetium (La-Lu) in the periodic table, plus scandium (Sc) and ytterbium (Y). According to the U.S. Geological Survey, rare earths “are relatively abundant in the Earth’s crust, but mineable concentrations are less common than for most other mineral commodities.”

There are no lodes of rare earth elements (REEs) as there are of gold and copper. But some parts of the world contain ores with high enough concentrations of REEs to extract profitably. China has the largest known reserves of REEs, at 44.0 metric tons (MT), followed by Brazil (21.0 MT), Canada (over 14.0 MT), Australia (5.7 MT), and the U.S. (3.6 MT). Reserves of the less abundant, more valuable “heavy” REEs (dysprosium, yttrium, and others) are, again, largest in China, Southeast Asia (Vietnam in particular), and Brazil.

It’s hard to overstate the importance of REEs. Their magnetic, luminescent, electrical, and catalytic properties make them indispensable in applications ranging from iPhones to Tesla engines to LED lights, from aircraft and drones to sensors, precision-guided munitions, and nuclear reactors.

Rare earth metals are a critical additive to the so-called permanent magnets used in defense equipment, power generation, and vehicles. They “improve magnetic efficiency and a magnet’s resistance to demagnification,” says Tom Moerenhout, professor at the Columbia University School of International and Public Affairs and leader of the critical minerals initiative at the school’s Center on Global Energy Policy. “Just a small amount of REEs makes a drastic improvement.”

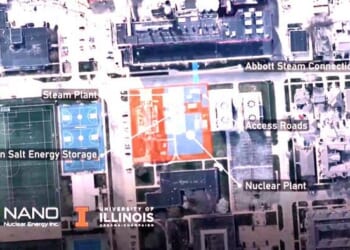

Moerenhout says REEs are most important “for permanent magnets that translate kinetic energy into electrical energy, or vice versa.” Think turbines converting wind or steam into electricity, he says, or a battery powering an electric car’s acceleration.

How China conquered the rare earths.

China entered the REE industry four decades ago and almost totally dominated REEs from the early 2000s to the early 2010s, after which the rest of the world re-entered the sector. Over those four decades, China has mastered the most difficult, most expensive part of the REE industrial process—separating and refining REEs from other dissolved minerals after they are mined.

Separating heavy REEs “is the most critical bottleneck” in the production process, says Moerenhout. It’s technologically complex, requiring highly specialized solvents and infrastructure that takes decades to build. Further, “[m]ining, separation, and magnet manufacturing all need to click into place at the same time for production to proceed smoothly,” according to Chemical & Engineering News.

Another processing challenge, says Moerenhout, is handling the resulting waste. REEs are stripped from ores and minerals containing natural levels of uranium and thorium, according to the Environmental Protection Agency, resulting in radioactive waste. Processing one metric ton of rare earth metals can produce 2,000 MT of toxic waste, but China’s comparatively lax environmental standards have given its REE producers free rein to dominate the global industry. The Chinese government’s recent acknowledgment of “cancer villages” near mine sites may have weakened its tolerance for this risk.

“After four decades of practice and improvement,” economics writer Noah Smith explains, China “got incredibly good” at refining REEs. “The U.S., meanwhile, has almost zero expertise in this area.”

As of 2024, China was still producing 70 percent of the world’s rare earths, but it has a virtual monopoly on refining REEs. In fact, all heavy REEs mined in the U.S. are sent there for processing. China processes almost 90 percent of mined REEs, produces close to 99 percent of the world’s supply of heavy rare earth metals, and makes 90 percent of the world’s supply of rare earth magnets, of which it is the world’s low-cost producer.

Fear in a handful of dust.

The Trump administration’s tariff announcements in early April served to heat up simmering tensions with China over rare earth minerals. China responded immediately with restrictions on six heavy rare earths, all of them refined only in China, and on rare earth magnets.

After the Trump administration backed away from its tariff threats, China eventually allowed exports through short-term agreements. But it did not rescind its restrictions.

In July, California-based MP Materials announced a remarkable deal with the Department of Defense that included a $150 million loan intended to fund the building of a rare earths separation facility. Currently, ore mined by the company goes to China for processing, refinement, and some magnet manufacturing, and refined REEs are shipped back to the U.S. for magnet manufacturing. The deal’s goal is to take China entirely out of the production midstream, says Moerenhout.

That strategy is now complicated by China’s October 9 announcement, ahead of a planned meeting between President Donald Trump and Chinese President Xi Jinping, of a host of additional export controls on REEs and REE-derived products, including permanent magnets. These include restrictions on exports of items made outside China that contain 0.1 percent or more of Chinese technology, as well as prohibitions on exports to non-Chinese companies that have any attachment to non-Chinese militaries.

That raised the REE crisis to its current fever pitch. Treasury Secretary Scott Bessent quickly promised an Operation Warp Speed-type response to the U.S. rare earth supply. But China Briefing believes China’s restrictions should be taken with a small grain of salt. They appear “not intended as an outright export ban, but rather as a means for Beijing to exercise tighter administrative control and oversight over the flow of strategic resources.” China can hasten or slow the global supply of REEs with red tape.

Companies that rely on REEs should expect similar disruptions later this fall, when these restrictions take effect, according to the same publication. And countries seeking to reshore permanent magnet production won’t be able to do so unless they use REEs that are not sourced from China.

REE shortages could get personal. Your Apple device relies heavily on REE magnets for haptics, audio equipment, and microphones, according to the Institute for Energy Research. A rare earth shortage shut down production of the Ford Explorer in May, and a similar shutdown befell Suzuki’s Swift car in Japan.

Can the U.S. compete?

“‘In about a year from now, we’ll have so much critical minerals and rare earths that you won’t know what to do with them.’” That was President Trump’s promise on Monday after signing a pact with Australian Prime Minister Anthony Albanese for the two countries to spend $3 billion on critical minerals projects—including REEs—in the next six months.

Even accounting for Trump’s trademark hyperbole, the president’s optimism is shared, at least in part, by more than a few knowledgeable observers. Peter Harrell, a visiting scholar at the Georgetown Institute of International Economic Law, believes China’s export controls will be “clearly harmful to the west, [but] less effective than they expect.” He thinks the solution is a combination of substantial investment, massively streamlining permits, encouraging demand for non-Chinese product, “friend-shoring” (producing REEs with allies), and stockpiling. He’s optimistic that China’s restrictions are the shock the West needs to get moving on its own processing capabilities.

Smith also believes the road ahead is daunting but points to the experience of Japan, which faced similar REE restrictions by China in 2010 and reduced its dependence on rare earths from China from more than 90 percent of imports to 58 percent within a decade. Smith also points to a “very deep reservoir of innovative capacity” in the U.S. For example, researchers have successfully extracted REEs from coal mine pit wastewater in West Virginia and from coal waste in Indiana. One researcher calculates there may be enough REEs in existing U.S. wastewater pits to supply the U.S. defense industry.

But as Harrell makes clear, REE independence is going to be expensive. In the MP Materials deal, the U.S. is providing a guaranteed purchase of products at a guaranteed profit margin for the company. The government’s 15 percent equity stake may pay off—or it may be another Solyndra. And the degree of government intervention—“unprecedented,” says Moerenhout—could set a poor precedent. “It’s worrisome,” says Harrell. “It’s picking winners and opens the door to government to meddle in the details.”

Cleaning up the toxic waste and remediating the environmental damage to a politically acceptable level will also be very costly, and likely borne by taxpayers.

Independence from China will also call for more alliances like the one signed Monday with Australia. None of this will be easy, Smith believes, but shrewd U.S. policy could turn the table and “break the economic yoke that China has placed around our neck—and the whole world’s neck.”